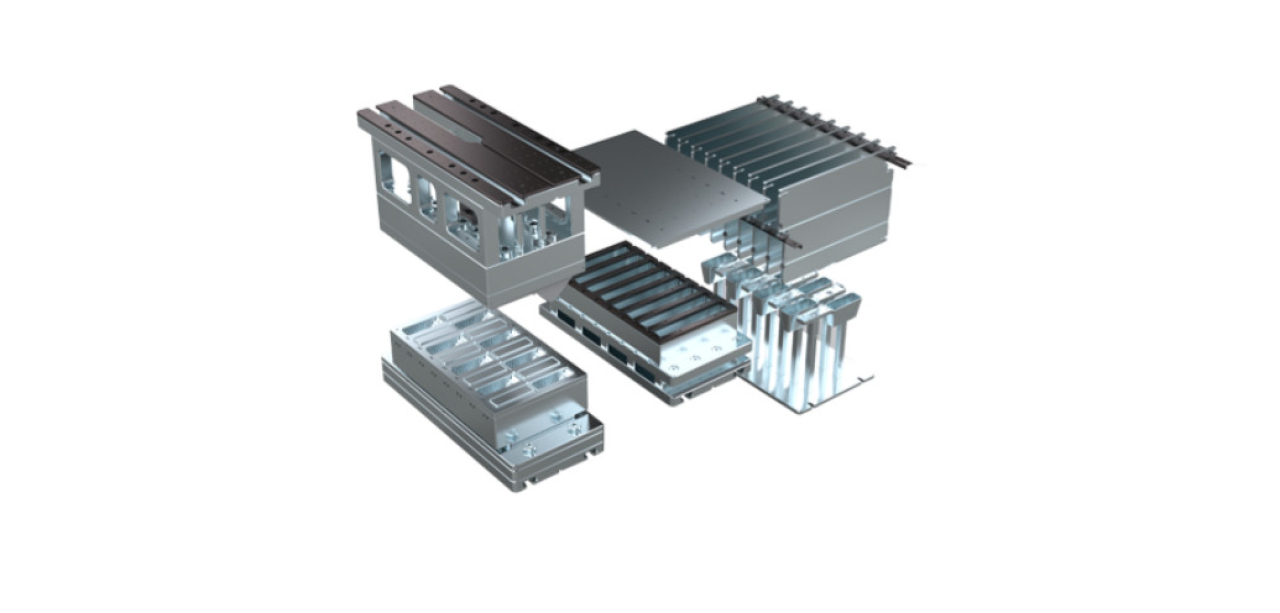

What is 3 Station Tooling?

3 Station Tooling refers to a specialized tool or mold design used in manufacturing processes that allows three distinct operations or processes to take place in one unified setup. This multi-station system is designed to optimize production cycles by performing multiple functions—such as heating, molding, and cooling—simultaneously or in quick succession. The design typically incorporates three separate stations, each dedicated to a specific part of the process, and works efficiently together to streamline the entire production flow.

Each station within the 3 Station Tooling system is responsible for a different task:

Station 1 – Material Preparation (Heating or Injection).

Station 2 – Shaping/Forming (Molding or Pressing).

Station 3 – Cooling and Ejection (Solidification and Removal).

By combining these steps into a single machine or system, manufacturers can reduce downtime, minimize manual interventions, and optimize the overall production process. The result is faster cycle times and a more efficient manufacturing workflow, which translates to lower costs and higher throughput.

How Does 3 Station Tooling Work?

The functionality of 3 Station Tooling can be best understood by examining each of the stations involved:

Station 1: Material Preparation (Heating or Injection)

In this initial stage, the raw material, such as a plastic sheet in thermoforming or molten plastic in injection molding, is prepared. For thermoforming, this involves heating the plastic sheet until it becomes flexible enough to conform to the mold. In injection molding, the material is injected into the mold cavity in a molten state. This stage is essential as it ensures that the material is in the correct form and temperature to undergo the subsequent shaping process.

Station 2: Molding/Shaping

The second station is where the shaping or molding process occurs. In thermoforming, the heated material is draped over or into a mold, where it takes the shape of the mold cavity through the application of pressure or vacuum. In injection molding, the material fills the cavity and takes the shape of the mold once it cools. This step is where the product starts to take its final form, and it is crucial that the mold is designed with high precision to ensure accurate results.

Station 3: Cooling and Ejection

After the molding or shaping process is complete, the material needs to cool and solidify. In this third station, cooling systems such as water or air channels in the tooling are used to lower the temperature of the molded part. Once the plastic has solidified, it is ejected from the mold. Depending on the design of the tooling, this process can be automated to enhance speed and minimize manual handling.

Advantages of 3 Station Tooling

The integration of multiple stages into a single tool with 3 Station Tooling provides several key advantages over traditional single-stage tooling:

Increased Production Efficiency

The most significant advantage of 3 Station Tooling is its ability to streamline the manufacturing process. By combining three stages of production into a single tool, manufacturers can reduce the number of setups, machine changes, and downtime. This leads to faster cycle times and higher throughput, which ultimately improves overall production efficiency.

Cost-Effective Production

Using a 3 Station Tooling system can be more cost-effective than using separate tools for each stage of production. The need for fewer machines, less tooling, and reduced setup times means lower capital and operational costs. Additionally, the high efficiency of the system allows for greater production volume, which can lead to economies of scale and further cost savings.

Higher Precision and Consistency

Since all three stages are carried out in a single unified system, there is less room for variation between each stage. The synchronization between the heating, molding, and cooling stations ensures that the parts are formed with greater precision and consistency. This is particularly important for industries where high-quality standards and tight tolerances are required, such as the automotive, medical, and electronics sectors.

Reduced Material Waste

3 Station Tooling systems are often designed to minimize material waste. The integrated system ensures that the material is used efficiently throughout the process, reducing excess material and scrap. The high level of control over the molding and cooling process also minimizes the likelihood of defects, which in turn reduces the amount of material that must be discarded.

Flexibility in Production

The versatility of 3 Station Tooling makes it ideal for producing a wide range of products. Manufacturers can design the system to accommodate different materials, mold shapes, and production volumes, making it suitable for both small and large-scale manufacturing. The system’s flexibility also allows for easy adjustments to accommodate different product specifications or design changes.

Applications of 3 Station Tooling

The versatility and efficiency of 3 Station Tooling make it highly applicable in a variety of industries. Some of the most common applications include:

Packaging

The packaging industry relies heavily on 3 Station Tooling to produce items like blister packs, trays, and clamshell packaging. These products require precise molding and fast production cycles, making the integration of heating, molding, and cooling into one system ideal for mass production.

Automotive

The automotive industry benefits from 3 Station Tooling for producing interior components such as dashboards, trim pieces, and door panels. These parts require both high precision and fast production times, and the tooling system’s ability to integrate multiple steps into one machine helps meet these demands efficiently.

Medical Devices

In the medical industry, precision and reliability are critical. 3 Station Tooling is used to produce medical trays, containers, and sterile packaging, ensuring that the products meet stringent quality standards while being produced quickly and efficiently.

Consumer Goods

From toys to household appliances, many consumer goods are manufactured using 3 Station Tooling. The ability to create a variety of shapes and sizes quickly makes it a popular choice for producing everyday items at high volumes.

Electronics

The electronics industry also utilizes 3 Station Tooling for producing housings, enclosures, and other components. The need for precise molding, quick cooling, and efficient production processes makes this tooling system an ideal choice.

Challenges and Considerations

While 3 Station Tooling offers numerous advantages, there are also some challenges and considerations to keep in mind:

Initial Setup Costs: Designing and manufacturing 3 Station Tooling can be expensive, especially for highly specialized molds or complex tooling systems. However, this cost is typically offset by the increased efficiency and cost savings over time.

Maintenance: As with any advanced tooling system, maintenance is crucial for ensuring the longevity and efficiency of the 3 Station Tooling. Regular checks and servicing are necessary to prevent wear and tear that could affect the quality of production.

Material Compatibility: Not all materials may be compatible with the 3 Station Tooling system. Careful consideration must be given to the properties of the material being used, as different materials may require different heating, cooling, or molding parameters.

3 Station Tooling is a game-changer in the world of manufacturing, offering significant advantages in terms of efficiency, cost-effectiveness, and precision. By integrating multiple stages of production into one system, it enables faster cycle times, higher throughput, and reduced material waste. Whether used in packaging, automotive, medical devices, or consumer goods manufacturing, 3 Station Tooling helps companies optimize their operations and stay competitive in an increasingly fast-paced market. By carefully considering the design, material compatibility, and maintenance of the tooling, manufacturers can maximize the benefits of this advanced system and improve their overall production capabilities.